Capacitive technology enables non-invasive bubble detection within critical fluid transfer lines. Typical applications include infusion pumps, kidney dialysis and microfluidic. Unlike optical bubble sensor, capacitive sensor can be used with a wider range of tubing materials and diameters. Another key benefit over optical is the reliability factor especially when used with fluids that stain the inner tubing walls (ex. blood).

Compared with an ultrasonic technology a capacitive sensor is roughly half the cost making it a cost effective solution for bubble detection. The two main drawbacks using capacitive are listed below:

- Sensor is only compatible with tubing sizes 1/4″ diameter OD or larger.

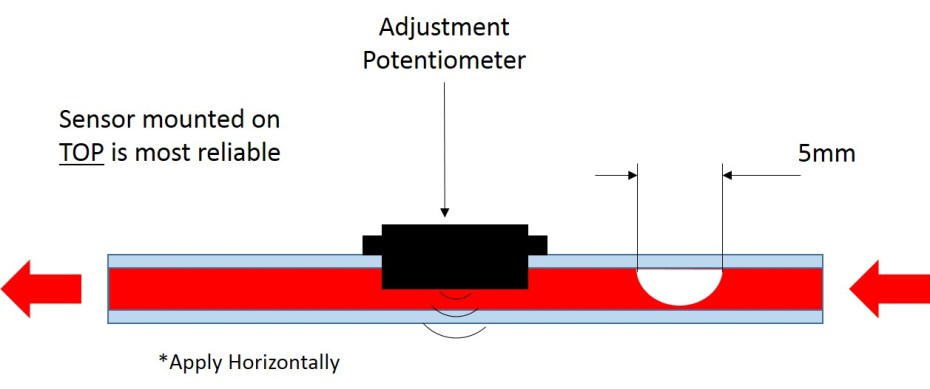

- An air gap of 5mm or larger is needed for stable detection. Micro-bubbles are not detected by capacitive sensors.

Setup Procedure

- Install capacitive sensor onto a filled tube. Make sure the sensing element is facing down on the tube.

- Once secured, turn potentiometer down until the output LED turns OFF.

- Slowly turn potentiometer up until the output LED turns ON.

- Slowly turn potentiometer back down without turning the LED OFF, then STOP

- * count the number of 1/2 circles it takes to turn the LED off

- ** adjust one 1/2 circle less than it takes to turn the LED off

- *** might be necessary to repeat steps 3~4 a few times

- The sensor is now tuned to the background and the output will turn OFF when bubble is detected.

Recommended part number: CP08-NF-12-NO