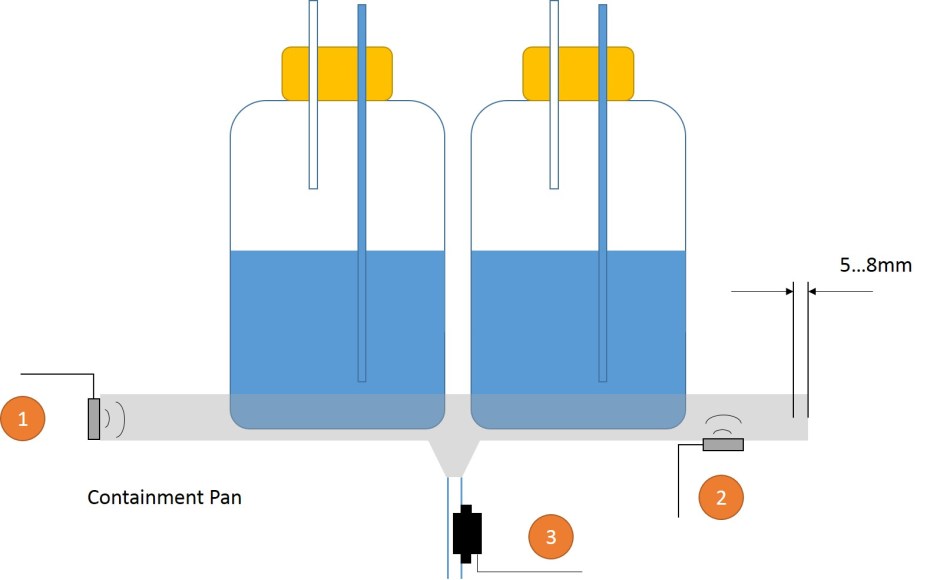

Capacitive sensor is a great non-invasive solution for leak detection. Besides the reliability of the technology, it is a cost effective alternative to higher cost leak sensors using optical or ultrasonic sensing methods. The ideal setup would require the use of a containment pan (non-metal), which physically collects the leaking fluid. The 3 most common locations to apply the leak sensor are below.

- Side Mount – placing capacitive sensor to the side of the pan. This method will take 3mm of fluid to activate the sensor.

- Under Mount – placing capacitive sensor under the pan. This method is most sensitive and will only take 2mm of fluid to activate.

- Drain Tube – attach a pipe mount capacitive sensor to a drain tube. This will minimize the size of the containment pan.

Setup Procedure

- Design a containment pan that is large enough to contain the leak or use a drain tube.

- Make sure the wall thickness is less than 8mm, side & bottom wall.

- Create a gradual slope on the pan where the leak sensor is mounted.

Recommended part number: CF07-NF-08-NC (ex. 1 & 2) CP08-NF-12-NO (ex. 3)