Optical leak sensor is the ideal measurement principle for heat transfer fluids used in semiconductor equipment. The technology is highly reliable and function based on the optical refraction difference between air and the target fluid. The setup would require the use of a containment pan (metal), which physically collects the leaking fluid and the sensor is placed inside the pan.

Key Features

- High temperature – Using high temperature rated materials and IC, the sensor can meet up to 120°C operating environment. Suitable for ALD and CVD application where heated gas boxes are common.

- Low temperature – Our sensor can operate at -40°C by using highly ridge materials to minimize thermal expansion/contraction. This allows ETCH application to run Galden to -40C or below without the risk of damaging the leak sensor.

- Dual output – The sensor has both a PNP and NPN output within a single detection circuit. This provides flexibility to use different output signals for various alarms.

| Sensor Model | Sensitivity | Mounting | Cable | Output | Description | ||

| H7L | Leak Sensor High Temperature | ||||||

| — | |||||||

| 02 | 2mm detection | ||||||

| TS | Cable (Top) Mounting (Side) 18mm | ||||||

| — | |||||||

| 03 | Cable Length (Meter) | ||||||

| PNC | PNP + NPN Normally Closed | ||||||

| Sensor Model | Sensitivity | Mounting | Cable | Output | Description | ||

| H7L | Leak Sensor High Temperature | ||||||

| — | |||||||

| 02 | 2mm detection | ||||||

| TE | Cable (Top) Mounting (End) 9mm | ||||||

| — | |||||||

| 03 | Cable Length (Meter) | ||||||

| PNC | PNP + NPN Normally Closed | ||||||

Product Specifications

| General Specifications | H7L |

| Supply Power | 12…24Vdc |

| Weight | 200g |

| Sensitivity | 1…2mm of fluid |

| Repeatability | +/- 1.0mm |

| Power Consumption | ≤ 38mA |

| Load Current | ≤ 100mA |

| Operating Temperature up to 72 Hrs | -40…120°C |

| Operating Temperature continuous | -30…110°C |

| Response Time | 100mS |

| Protection | IP 67 |

| Housing Material | SUS316L, borosilicate glass |

| Connection | 4-wire 3m cable (-60…200°C) |

| Output | Dual output (PNP NC + NPN NC) |

| Certification | CE, RoHS |

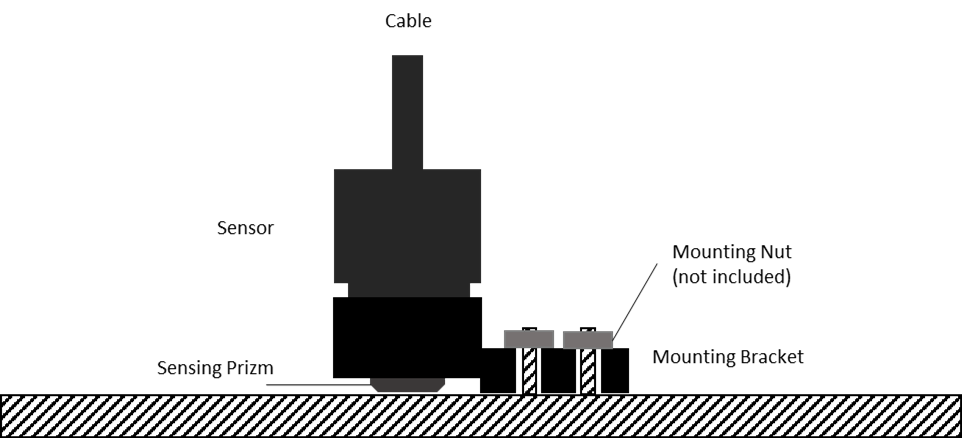

Mounting Configuration